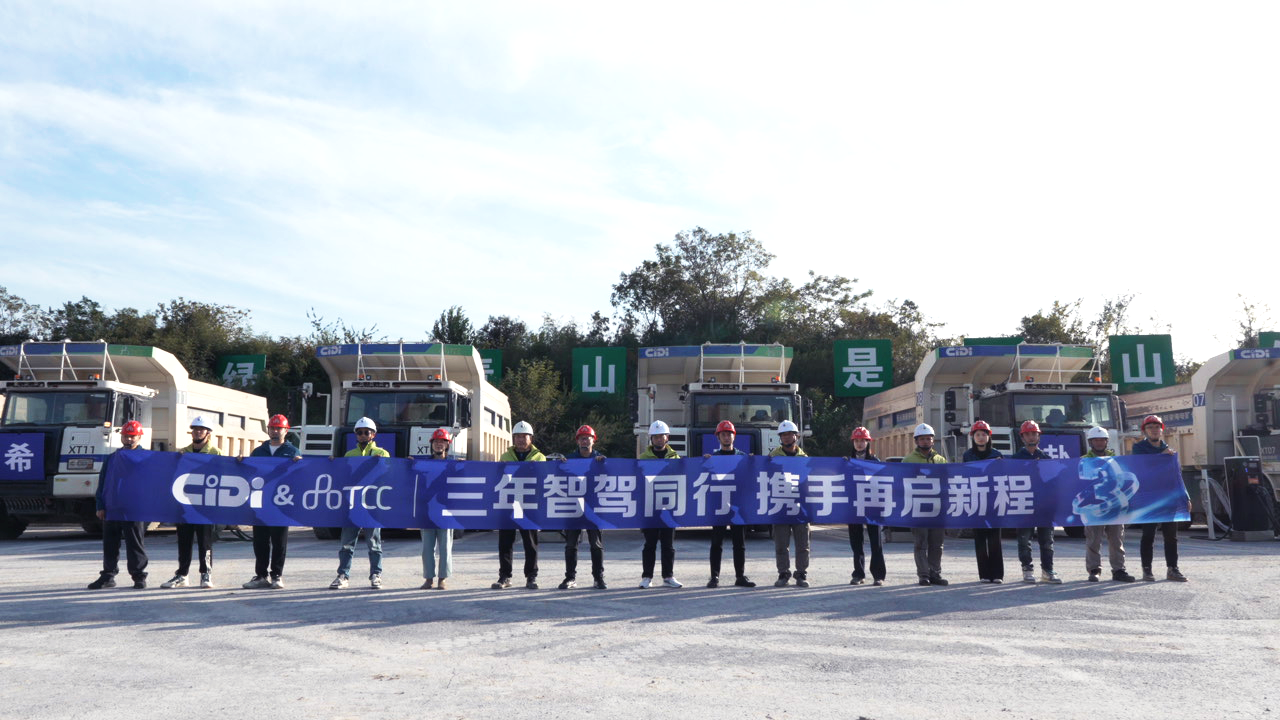

Forging the Efficiency Trifecta | CiDi and TCC Jurong Mine Celebrate Three Years of Safe Operations

As of November 2025, 14 fully electric unmanned mining trucks are operating autonomously at the Xiguoding limestone quarry, owned by Taiwan Cement Corporation(TCC)in Jurong, Jiangsu Province. These vehicles handle the full cycle of loading, transport, unloading, and charging—marking the third year of successful collaboration between CiDi and the TCC Jurong Mine on their autonomous driving initiative. Over the past three years, the project has achieved "Three Zeros": Zero Accidents, Zero Emissions, Zero Drivers — alongside 1.04× human-level efficiency and tens of millions of RMB in cumulative cost savings. It is now the world's longest-running fully electric autonomous mining fleet in continuous operation.

A Shared Breakthrough: Co-Innovation in Action

In 2022, a shared recognition of core industry challenges brought CiDi and TCC Jurong Mine together. At that time, TCC had announced its dual-drive strategy of "Low-Carbon + Intelligent Transformation." Meanwhile, the Jurong mine was facing mounting pressures: an aging frontline driver workforce, difficulty in recruiting younger talent, and tightened safety regulations following major national incidents such as the Xiangshui explosion. The traditional mining model was reaching its limits in both safety and efficiency.

Autonomous driving in closed industrial environments emerged as a key to breaking through. Despite the lack of mature, fully electric autonomous solutions in mine-wide domestically at the time, TCC chose to partner with CiDi, initiating an intensive co-development model. TCC provided unrestricted access to real-world mining scenarios, while CiDi deployed a dedicated on-site R&D team of several dozen engineers. To avoid disrupting daytime operations, the joint project team adopted a night shift model, beginning full-scale debugging work at midnight when the mine became quiet. Together, they overcame a series of technical challenges, including sensor interference in dusty conditions, seamless integration between autonomous vehicles and conventional production systems, and precise matching of electric drivetrains with heavy-duty haulage requirements.

In November 2022, a major breakthrough was achieved: on-site safety officers were officially removed from the trucks, and 14 fully electric, autonomous mining trucks—custom-developed by CiDi—replaced traditional diesel vehicles. Operating continuously for 7 days a week and 16 hours per day, the project became the world's first fully electric, mine-wide autonomous haulage system. It set a new benchmark for the industry's transformation toward "Safety + Low Carbon + Intelligence."

After three years of iteration and refinement, the project delivered outstanding results: over one million kilometers of zero-accident operation, efficiency reaching 1.04x that of human drivers, and significant cost savings through reduced energy consumption and maintenance needs.

This two-way commitment to deep collaboration has not only made TCC Jurong Mine a model of smart mining, but also validated the real-world implementation strength of CiDi's autonomous driving technologies.

Business Model Innovation: Empowering Through Technology for Long-Term Impact

The success of TCC Jurong Mine is deeply rooted in CiDi's differentiated business model.

Positioned as a deep-tech intelligent driving company for commercial vehicles, CiDi focuses on technology export and product sales rather than vehicle fleet operations. Instead, it builds a multi-stakeholder ecosystem: Collaborating with OEMs to deliver core autonomous driving solutions and share manufacturing and distribution capabilities; Partnering with tech firms in areas like chips and computing to complement hardware and software stacks; Working with energy providers to promote greener equipment transformation by integrating autonomous driving with core electrification systems—including battery, motor, and electronic control ("the three electrics"); Supporting mine operators with integrated ecosystem resources to deliver end to end solutions that enhance safety and efficiency while reducing operational costs and energy consumption.

At the core of CiDi's technology delivery is a "full-delivery" service model. It equips client teams like TCC's with both theoretical and hands-on training, while providing dedicated, on-site technical support 24/7. Over the past three years, TCC Jurong Mine has not needed to expand its operations team. The existing workforce now independently handles daily debugging, diagnostics, and autonomous fleet management. This "empowerment without replacement" model has earned CiDi real trust. TCC has continued to purchase from CiDi for its Hualian Mine and Yingde Mine, underscoring customer satisfaction.

By staying out of revenue competition with clients and focusing instead on enabling long-term value, CiDi has steadily grown its order volume. Its "MetaMine" autonomous solution has been deployed across more than 20 mines nationwide, including coal, metal, and aggregate sites.

Technology as a Shield: Enabling Performance Uplift

Behind three years of safe, efficient, and low-carbon operations lies CiDi's fully self-developed technical stack. Four core technological pillars provide a strong moat for scalable autonomous mining:

1. Advanced Onboard Intelligence to Handle Harsh Conditions

Heavy-duty mining trucks face unique challenges: massive vehicle mass, large blind zones, and harsh environments like dust, rain, and fog. CiDi adopts a "vehicle-centric, cloud-assisted" architecture, giving each vehicle high operational autonomy. Through deep software-hardware integration, the system enables complex intersection negotiation, trajectory prediction for moving targets, intelligent obstacle avoidance, and precise long-range detection. It can reliably detect pedestrians, vehicles, and rocks within 100 meters, with a minimum recognition accuracy of 10x10 cm.

2. High-Efficiency Fleet Coordination for Optimized Scheduling

With global path planning at its core, CiDi addresses the full spectrum of coordination challenges—including autonomous-to-autonomous vehicle interaction, human-autonomous vehicle integration, and vehicle-to-equipment collaboration—enabling end-to-end operational synergy across the site. The system supports multi-vehicle coordination, dynamic route planning, congestion avoidance, dispatch optimization, and intelligent charging strategies, ensuring seamless alignment between excavator loading and transport operations while minimizing queuing and bottlenecks. This capability is underpinned by CiDi's proprietary simulation platform, which can model complex real-world scenarios involving thousands of autonomous vehicles operating simultaneously, providing robust validation and decision support for deployment at scale.

3. Flexible Deployment for Rapid Adaptation

With deep experience across 20+ active mining projects, CiDi has developed a robust modular deployment framework. Its autonomous systems are decomposed into standardized function modules, supported by deployment toolchains that simplify engineering complexity. This enables rapid parameter adjustment and module tuning for various site-specific needs, accelerating scalable replication.

4. Production-Integrated Design for Economic Uplift

The real value of autonomy comes from production alignment. From real-time matching of trucks and excavators to mixed-mode operations and smart fleet scheduling, CiDi embeds its tech within every node of the mining workflow. The result is lower total cost of transport and measurable gains in overall productivity.

Together, these four core capabilities allow CiDi to form a distinct competitive edge: unrestricted operation across all mining scenarios, minimized idle time via precise scheduling, and reduced per-ton haulage costs via high-efficiency systems.

The success of TCC Jurong Mine is not just a technical achievement, but the beginning of a broader, shared future. It demonstrates that the smart mine is no longer a vision, but a reality. With this project as a blueprint, CiDi is ready to scale its proven Chinese solution to more mining sites, driving the global shift toward safer, more efficient, and more sustainable mining operations.